How to Ensure Long-Lasting Plastic Piping Installations

Understanding the Basics of Plastic Piping

Plastic piping systems are increasingly popular due to their durability, affordability, and versatility. They are used in various applications, from residential plumbing to industrial processes. However, to ensure these installations last for decades, it's crucial to follow best practices in installation and maintenance.

The longevity of plastic pipes depends on several factors, including the type of plastic used, the installation process, and the environmental conditions they are exposed to. Common materials include PVC, CPVC, and PEX, each with unique characteristics and suitability for different applications.

Choosing the Right Material

Selecting the appropriate material for your specific application is a critical step. Each type of plastic pipe has distinct properties:

- PVC (Polyvinyl Chloride): Ideal for cold water applications and drainage systems.

- CPVC (Chlorinated Polyvinyl Chloride): Suitable for hot water applications due to its higher temperature tolerance.

- PEX (Cross-Linked Polyethylene): Flexible and resistant to both hot and cold temperatures, making it perfect for various plumbing needs.

Consider factors such as temperature, pressure, and chemical exposure before making a decision. Consulting with experts or manufacturers can provide valuable insights into the best material for your project.

Proper Installation Techniques

Ensuring long-lasting plastic piping installations begins with proper installation techniques. Here are some key steps:

- Thorough Planning: Plan the layout carefully to minimize the number of joints and fittings, reducing potential weak points.

- Correct Cutting and Joining: Use appropriate tools to cut pipes cleanly and ensure proper alignment when joining sections.

- Secure Fittings: Use high-quality fittings and follow manufacturer guidelines to ensure secure connections.

Avoiding Common Mistakes

Avoiding common installation mistakes can significantly extend the life of your piping system. One frequent error is applying excessive force during installation, which can damage the pipes. Ensure that you do not overtighten joints or fittings, as this can lead to cracks or leaks over time.

Another mistake is failing to account for thermal expansion and contraction. Plastic pipes expand with heat and contract with cold, so allowing for movement within the system is essential. Using expansion loops or offsets can help accommodate these changes.

Regular Maintenance and Inspection

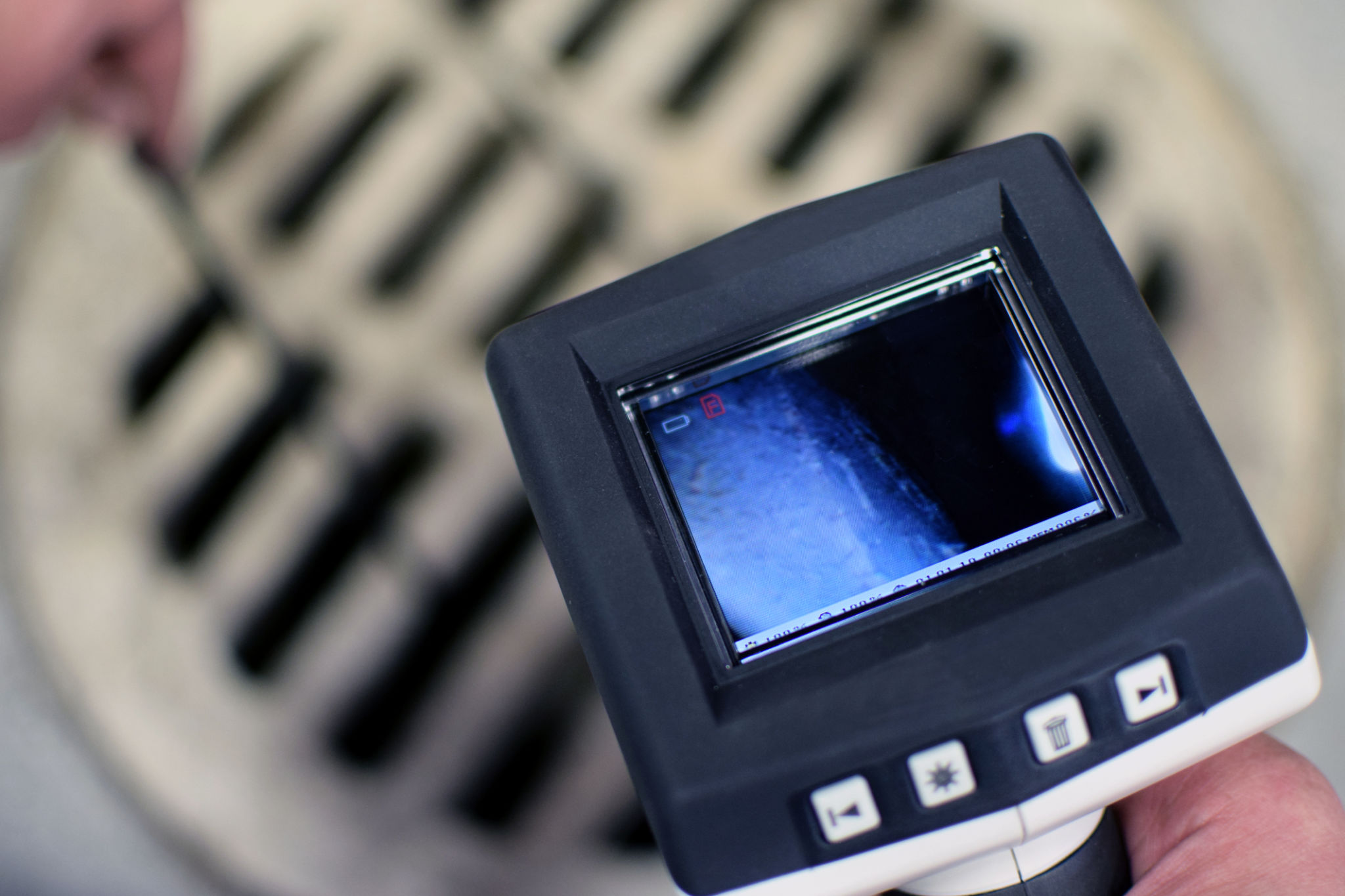

Once installed, regular maintenance is key to ensuring the longevity of your plastic piping system. Conduct periodic inspections to identify any signs of wear or damage early. Look for leaks, discoloration, or any unusual noises that may indicate a problem.

Preventive Measures

Implementing preventive measures can also help extend the life of your plastic pipes. For instance, insulating pipes in areas exposed to temperature extremes can prevent cracking or damage. Additionally, avoid exposing pipes to direct sunlight or harmful chemicals that can degrade the material over time.

By following these guidelines and being proactive about maintenance, you can ensure that your plastic piping installations remain reliable and efficient for many years to come. Investing time and effort upfront in proper selection, installation, and care will pay off in reduced repair costs and increased system longevity.